Sustainability

To achieve sustainable growth, Sekisui Medical engages in sustainability activities to improve the quality of Our Business while fulfilling our social responsibilities and creating value according to the SEKISUI CHEMICAL Group Vision.

SEKISUI CHEMICAL Group upholds "Innovation for the Earth: In order to realize a sustainable society, we support the basis of LIFE and will continue to create peace of mind for the future" as the Group's vision.

Through our core business, we will contribute to solving the challenges outlined in the SDGs proposed by the United Nations in 2015. We are promotinges a variety of sustainability initiatives that are integrated with Our Business activities to address challenges faced by society.

"EcoVadis Sustainability Rating – Bronze Medal (2025)"

In 2025, EcoVadis (headquartered in France), an international sustainability evaluation organization, ranked Sekisui Medical Co., Ltd. among the top 19% of companies in the evaluation and awarded a Bronze rating. The Bronze rating is given to companies in the top 35%. EcoVadis evaluates the sustainability of more than 150,000 companies in 185 countries from 4 perspectives: environment, labor and human rights, ethics, and sustainable procurement. our company will continue to strengthen its sustainability initiatives throughout its corporate activities and promote activities that take society and the environment into consideration.

Our Initiatives

For the global environment

The Sekisui Medical Environmental Charter

We strive to be a company that creates a healthy environment, and that achieves sustainable growth with 'the environment' as our cornerstone.

To achieve this goal:

- 1Each one of us pays due consideration to the environment in our actions at work.

- 2Each one of us also engages in environmentally-friendly action at home and in the local community.

To realize a decarbonized society

Sekisui Medical has set a long-term goal of achieving zero greenhouse gas (GHG) emissions by 2050 in order to realize a decarbonized society. To achieve this goal, we are promoting GHG reduction activities through the effective use of energy through the installation of energy-saving and high-efficiency facilities, and the installation of renewable energy generation facilities. Specific initiatives include the conversion of boiler fuel from heavy oil to LNG (switching to low-GHG emission fuels), the installation of high-efficiency boilers and a solar power generation systems, and the conversion of purchased electricity to 100% renewable energy. The medium-term goal is to reduce GHG emissions by 50% from the FY 2019 level by FY 2030. In FY 2024, two domestic plants and all research institutes completed the conversion to renewable energy sources and achieved zero GHG emissions from electricity.

In addition, we have assigned persons who are certified as “Environment Legal Leader (ELL)” by Sekisui Chemical Group to each business establishment, and is working to comply with environmental laws and regulations and prevent environmental incidents.

Our Commitment to the Environment

- Tsukuba Plant

-

The Tsukuba Plant is located in the Tsukuba-no-sato Industrial Park in Ryugasaki, Ibaraki Prefecture, and manufactures in vitro diagnostics along with reagents for research use. The Plant implements environmentally friendly measures including the use of renewable energy, the cultivation of native plant species, and the removal of introduced plant species. It acquired ISO 14001 Environmental Management System certification in September 2011 (assessment and registration) and actively engages in efforts to protect the environment.

- Ami Office

-

The Ami Office is located in the Fukuda Industrial Park in Ami-machi, Inashiki-gun, Ibaraki Prefecture. It manufactures in vitro diagnostics and reagents for research use. The office implements environmentally friendly initiatives, such as the energy-saving operation of its manufacturing equipment, garbage separation and processing, and clean up campaigns. The Ami Office acquired ISO 14001 Environmental Management System certification in May 2006 (assessment and registration) and actively engages in efforts to protect the environment.

- Tokuyama Plant

-

The Tokuyama Plant is located in the Shunan Industrial Complex in Yamaguchi Prefecture, and manufactures vacuum blood collection tubes, diabetes diagnosis columns, and eluents. The Plant has reduced waste and since 2000 has been maintaining a forest leased from Shunan City. In March 2000, the plant obtained the ISO 14001 environmental management system certification (assessment and registration), and is committed to environmental protection.

- Iwate Plant

-

The Iwate Plant is located in a scenic area with views of the majestic mountains of Towada-Hachimantai National Park, offering a setting rich in natural beauty.All electricity used at the plant is derived from 100% renewable energy sources, reflecting our strong commitment to environmental sustainability. We have implemented a range of eco-friendly initiatives, including the installation of LNG boilers and the effective utilization of methane gas generated from our wastewater treatment system. These efforts are part of our broader mission to coexist harmoniously with the irreplaceable natural environment surrounding the plant. In addition, the plant obtained ISO 14001 in February 2001 certification and has since been continuously developing its environmental management system. In 2023, it was certified one of the “Nationally Certified Sustainably Managed Natural Sites” by Japan’s Ministry of the Environment, and continues to pursue environmentally conscious production activities.

- Drug Development Solutions Center

-

The Drug Development Solutions Center is located in Tokai-mura, Ibaraki Prefecture, and conduct safety studies of pharmaceuticals. The Center is involved in a number of environmental initiatives, including the installation of LNG boilers , the use of renewable energy, waste separation, the reduction of copier paper usage, and the implementation of a clean up campaign. The Plant acquired ISO 14001 Environmental Management System certification in July 2024 (assessment and registration) and actively engages in efforts to protect the environment.

For secure and enriched lifestyles of all people.

Vacuum blood collection tubes and diagnostic agent systems

We were the first in the world to introduce plastic vacuum blood collection tubes, helping to prevent breakage during examinations. The testing system, which integrates the steps of blood collection, testing and results, combined with test instruments, enables us to confirm the cause of the disease at an early stage and use the results for treatment, thereby contributing to the early detection of diseases by improving the efficiency of medical care.

Fostering a Corporate Culture to Embrace Challenges

Our Approach to Human Resource Development

Based on our belief that employees are precious assets bestowed on us by society, we, SEKISUI CHEMICAL Group, are committed to developing an environment where employees can work enthusiastically. We also offer various opportunities through which we help individual employees enhance their specialties and grow personally through embracing challenges.

Sekisui Medical has established "Customer Focus" as one of its values to achieve the Group vision of "Creating a Healthy, Sustainable World." We launched the Customer Focus Project in 2021, which includes activities such as discussions between sales and other sites, hands-on training at sales and production sites, and temporary assignments to other departments. Through the project, we make the value of customer focus take root among our employees, while also allowing them to experience firsthand helping to solve social challenges.

Deepening Engagement

SEKISUI CHEMICAL Group periodically conducts the engagement survey targeting all employees every three years. We assert that continued empathy with and undertaking of our Vision, as well as each individual employee is always the key players; the sense of belonging in the company, passion for work and willingness to contribute, in other words engagement, is crucial for achieving the SEKISUI CHEMICAL Group Long-term Vision, Vision 2030.

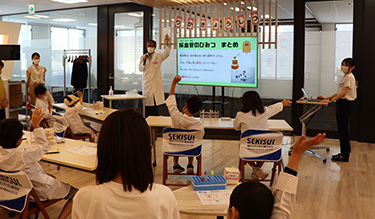

Promotion of Social Contribution Activities

Empowering the Next Generation

As part of our social contribution activities, which are one of our key action guidelines, we are actively engaged in next-generation education. In FY2024, we organized two science classes: an "in-hospital program" for children hospitalized at a children's hospital, and a "sibling program" for their brothers and sisters. In these classes, our employees acted as instructors, offering the children opportunities to explore the wonders of nature and technology through hands-on experiments and exposure to science. Through these activities, we aim to foster a spirit of inquiry in the children.

Continuing to contribute to society

SEKISUI CHEMICAL Group is striving to improve management ability to sustain business by thoroughly improving compliance, and CS & Quality. These efforts are aimed at reducing risk and avoiding serious incidents (in terms of safety, quality, accounting, legal and ethical issues, and information management).

CS Quality Management

CS Quality is our management cornerstone. In all of Our Business activities, we seek meticulously innovations to improve product quality, and provide products and services that live up to customer expectations. We want our customers to continue to choose us, and aim at to achieve long-term growth and sustainable development along with our customers.

Quality initiatives in each business

- Diagnostics Business

- The Tsukuba Plant has established a quality management system based on the QMS Ministerial Ordinance on Standards for Manufacturing Control and Quality Control for Medical Devices and In-Vitro Diagnostics to supply high-quality products worldwide.

We continue to hold ISO9001 certification (acquired in March 2004) and ISO13485 certification (acquired in March 2005). In 2017 the Ami Office was added to the Tsukuba Plant as a new manufacturing base, and we completed the update to ISO9001:2015 and ISO13485:2016.

The Tokuyama Plant has also established a similar quality management system based on ISO 13485 (acquired in April 2005) and ISO 9001 (acquired again in March 2025 following the succession of business from Tokuyama Sekisui Co., Ltd.).

- Pharmaceuticals & Fine Chemical Business

- Based on ministerial ordinances with regard to GMP for pharmaceuticals and medicated products, the Iwate Plant manufactures high-quality chemicals, with a particular focus on APIs, pharmaceutical intermediates, and food additives. We are registered with the American FDA and official bodies in the EU and elsewhere, and we ship APIs not only within Japan but also to the global market.

- Drug Development Solutions Business

- The Drug Development Solutions Center has conducted non-clinical drug safety studies in accordance with the Ministerial Ordinance on Good Laboratory Practice for Nonclinical Safety Studies of Drugs (GLP Ordinance). The Center has received a conformity of assessment/results in the survey on toxicokinetics (TK) test by the Pharmaceuticals and Medical Devices Agency while assisting pharmaceutical companies in Japan and overseas in the development of new drugs.

Initiatives to Foster a Healthy Global Quality Culture

We are constantly emphasizing quality and have developed a program specifically to ensure that our quality culture is being reinforced. Additionally, we have launched this program globally. We are quite aware of the relationship between a robust quality culture and the influence it has on the quality of products and services provided.

All Sekisui Medical Group companies located in Japan, North America, Europe and Asia share a common commitment to our Quality Culture Statement and employees at every level of the company are actively involved in enhancing the quality culture.

- Quality Culture Statement

-

- 1We evaluate and plan with Quality as our focus

- 2We decide based on our core values and our commitment to Quality

- 3We act to achieve and maintain high Quality

(Extract from the Sekisui Medical Quality Culture Statement)

We are dedicated to a Quality Culture recognizing the performance of our products and services is what contributes to the improvement of patient care worldwide.

Legal / Compliance

Based on the spirit of the conduct guidelines set forth in the Corporate Activity Guidelines, we have delivered on our commitment to earn the high trust from our society through serving compliance with the laws and the spirit of the laws and acting with integrity in our all corporate activities. We will continue our efforts to improve compliance awareness.

Growing Awareness Toward Compliance

SEKISUI CHEMICAL Group has created and distributed the Compliance Manual, in which are described the matters with which each Group employee should comply, and also created a pocket version called the Compliance Card in order to instill awareness of compliance in each and every employee. The Compliance Manual includes information on topics such as the prohibitions on corruption and bribery, respect for human rights and the prohibition of discrimination, data management and protection, compliance with antitrust legislation, prohibitions on insider trading, conservation of the global environment and compliance with labor-related laws and regulations, and the internal whistleblowing system; it publicizes, and promotes thorough adherence with these requirements among all employees.

Compliance Training

As part of our efforts associated with putting compliance management into practice, we also focus on employee compliance education. We continuously provide opportunities for all Group employees to learn about the importance of compliance, such as by conducting e-learning sessions specific to compliance . These e-learning programs include information about compliance as training for new employees and as rank-specific training.

Initiatives to Strengthen Accounting Compliance

SEKISUI CHEMICAL Group is working to improve accounting skills and financial expertise across the Group as a whole in order to reduce risks related to finance and accounting.

we conduct accounting workshop meetings as well as e-learning sessions to provide training on accounting skills and financial knowledge, to prevent any incidence of accounting treatment error or accounting fraud, and to enhance the awareness of divisions and employees involved in accounting operations regarding compliance.